Application of LoRa wireless communication in smart factory energy data analysis and management

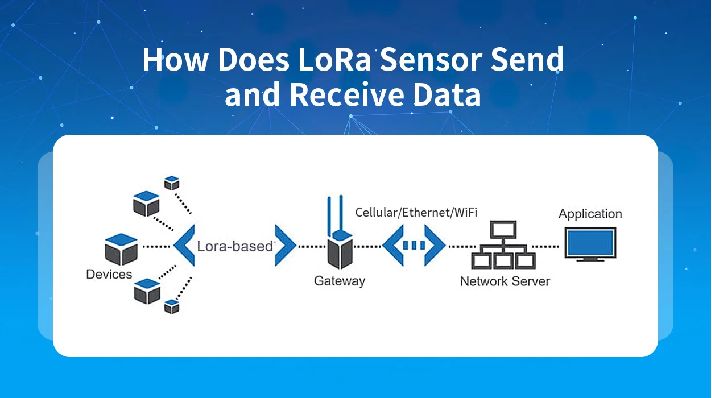

1. Introduction to LoRa technology

LoRa, the full name of Long Range, is one of the low-power wide area network (LPWAN, Low Power Wide Area Network) communication technologies. It uses advanced spread spectrum modulation technology and codec scheme to increase the link budget and better Anti-interference performance. LoRa's link budget of up to 157 dB enables the communication distance to reach more than 15 km (depending on the environment). It not only maintains the same low power consumption characteristics as FSK modulation, but also significantly increases the communication distance, while improving network efficiency and Interference is eliminated, that is, terminals with different spreading sequences will not interfere with each other even if they use the same frequency to transmit at the same time, and have better stability against communication deep fading and Doppler frequency shift.

Currently, LoRa mainly operates in free frequency bands around the world, including 433, 868,

915 MHz etc. This article uses the LoRa module in the 433 MHz frequency band, with a channel spacing of 2MHz, half-duplex, and transparent encrypted transmission to ensure data transmission security. It has the characteristics of long distance, low power consumption, multi-node, and low cost, and is suitable for building equipment that is widely distributed and widely separated. Communication network with long distance, anti-interference ability and low power consumption. This frequency band belongs to the ISM license-free frequency band, and there is no need to pay fees to the operator. There is less interference in this frequency band, and LoRa can well support communications in this frequency band.

2. On-site situation

At present, the multi-function electric energy meters in the medium-voltage switch cabinets in each electrical room of the cement factory, the multi-function electric energy meters in the main step-down medium-voltage switch cabinets and the multi-function electric energy meters in the metering cabinets, as well as the oil level, winding temperature and other equipment of the transformer are used. Signals, due to various factors such as design planning, wide distribution of equipment, and the particular location of the instruments, have not yet been connected to the DCS system for comprehensive monitoring and centralized management. Manual meter reading of each electric energy meter and manual inspection of power transformers are not only inefficient but also have high error rates.

High, and the demand for staff is large and the workload is heavy. Integrated automation and intelligence of smart factories also require the integration of the operating parameters of these instrumentation equipment into the DCS system for operation monitoring to achieve centralized automatic collection, monitoring and uploading, which provides real-time energy data analysis and management, historical energy data access, and equipment for smart factories. Real-time online monitoring provides data sources.

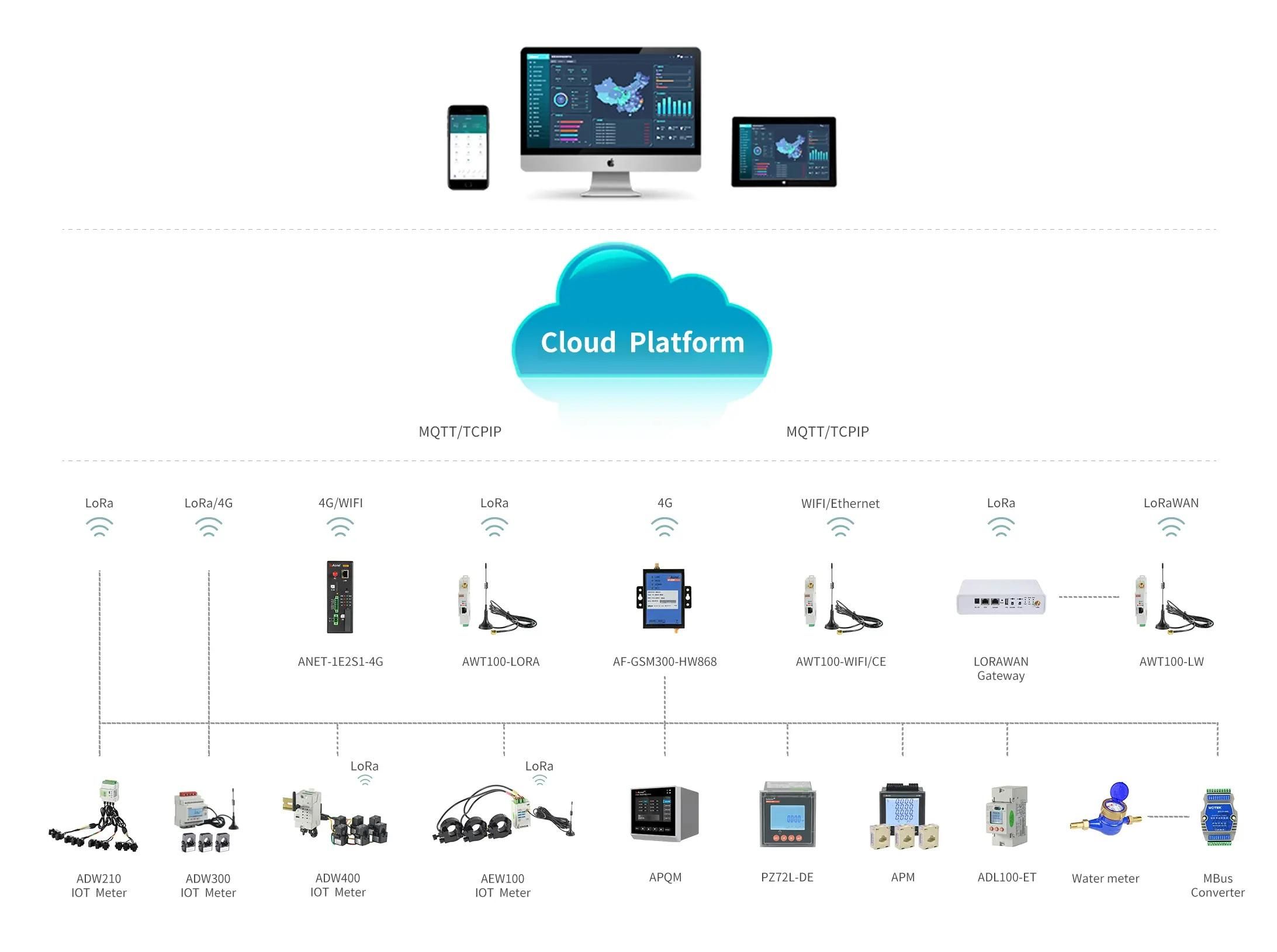

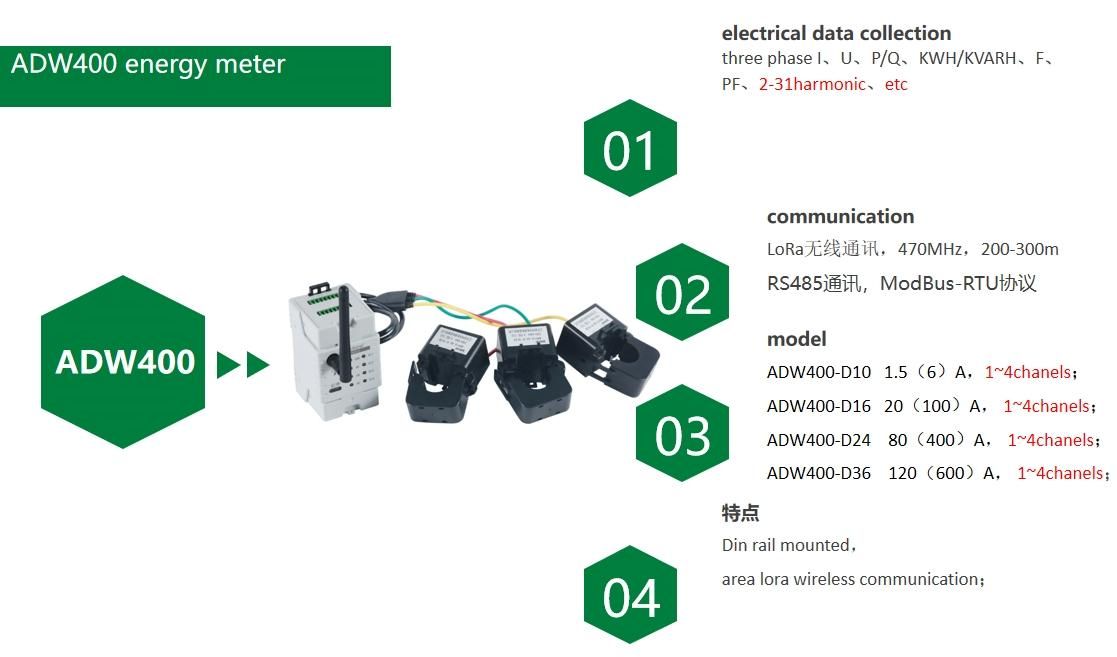

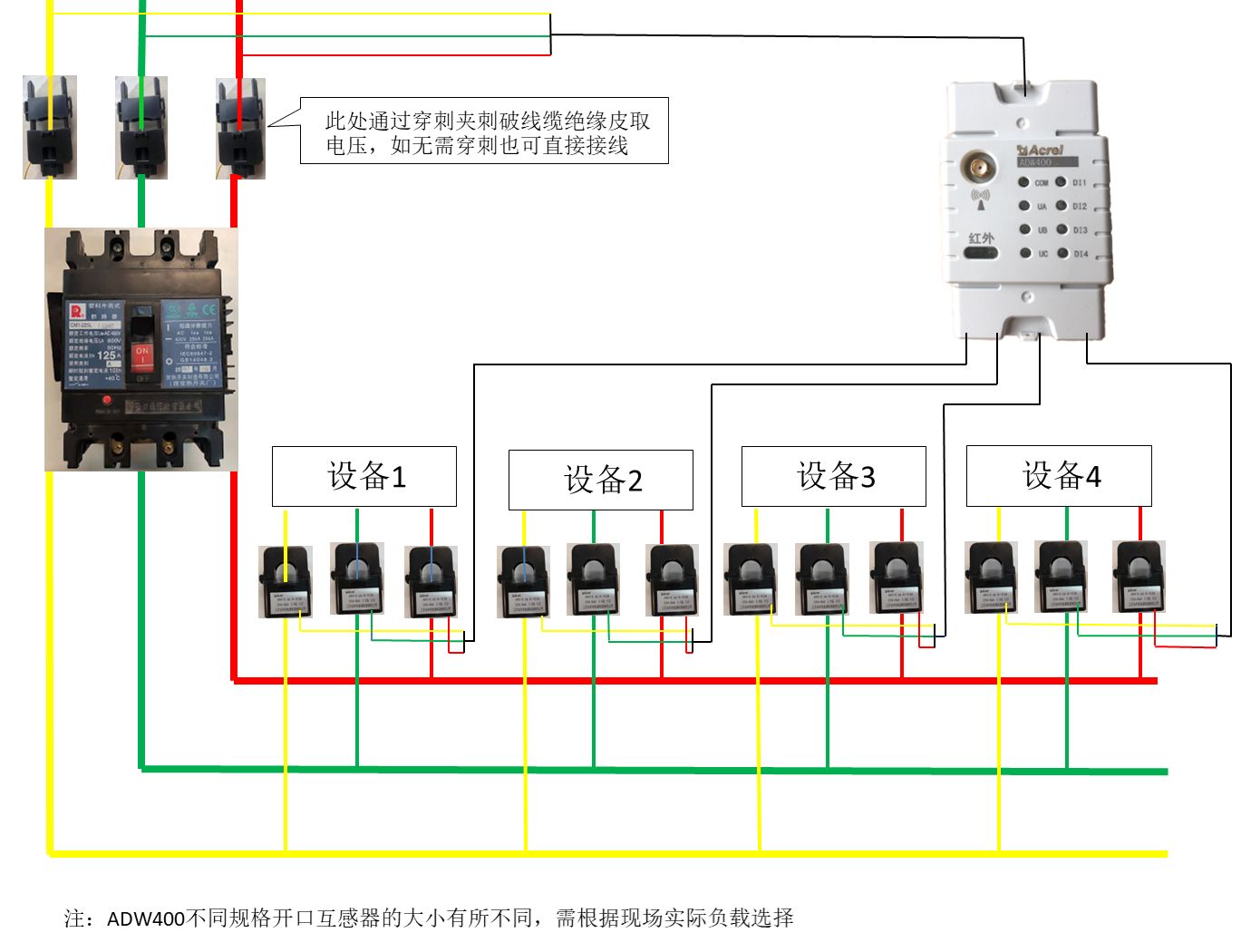

Intelligent instrument equipment such as multi-function electric energy meters and transformer remote temperature indicators generally have EIA-485 communication interfaces. This article designs a remote data monitoring system based on LoRa wireless communication ad hoc network, using LoRa wireless communication Internet of Things technology, using LoRa wireless and 485 bus to form the network physical layer connection device, and Modbus-RTU is the data link layer and application layer. Communication protocol enables long-distance communication between various smart instruments and equipment. Through this network, real-time automatic collection and uploading of equipment signals such as multi-function electric energy meters, high-precision gate multi-function electric energy meters, transformer oil surface temperature in various electrical rooms and main step-down medium voltage cabinets at the project site is realized, realizing the integration between the DCS system and the smart factory. Centralized data collection and monitoring capabilities of these devices.

Acrel Lora wireless communication network Solutions